Need advice on which leak detection survey method is most accurate in locating leaks for your containment system? Maybe multiple surveys are applicable but don't know which one would fit your application. Or how about monitoring your application to determine if a leak has occurred? Whichever situation you are facing, our services and technical advice can help. We've provided many years of experience to our Clients to help determine which type of method is most effective and cost efficient. No need to stress over which survey works best for you, we'll figure that out!

Quality Assurance & Control for

Liner Installation

Service ID

QAQC - CMNT

DESCRIPTION

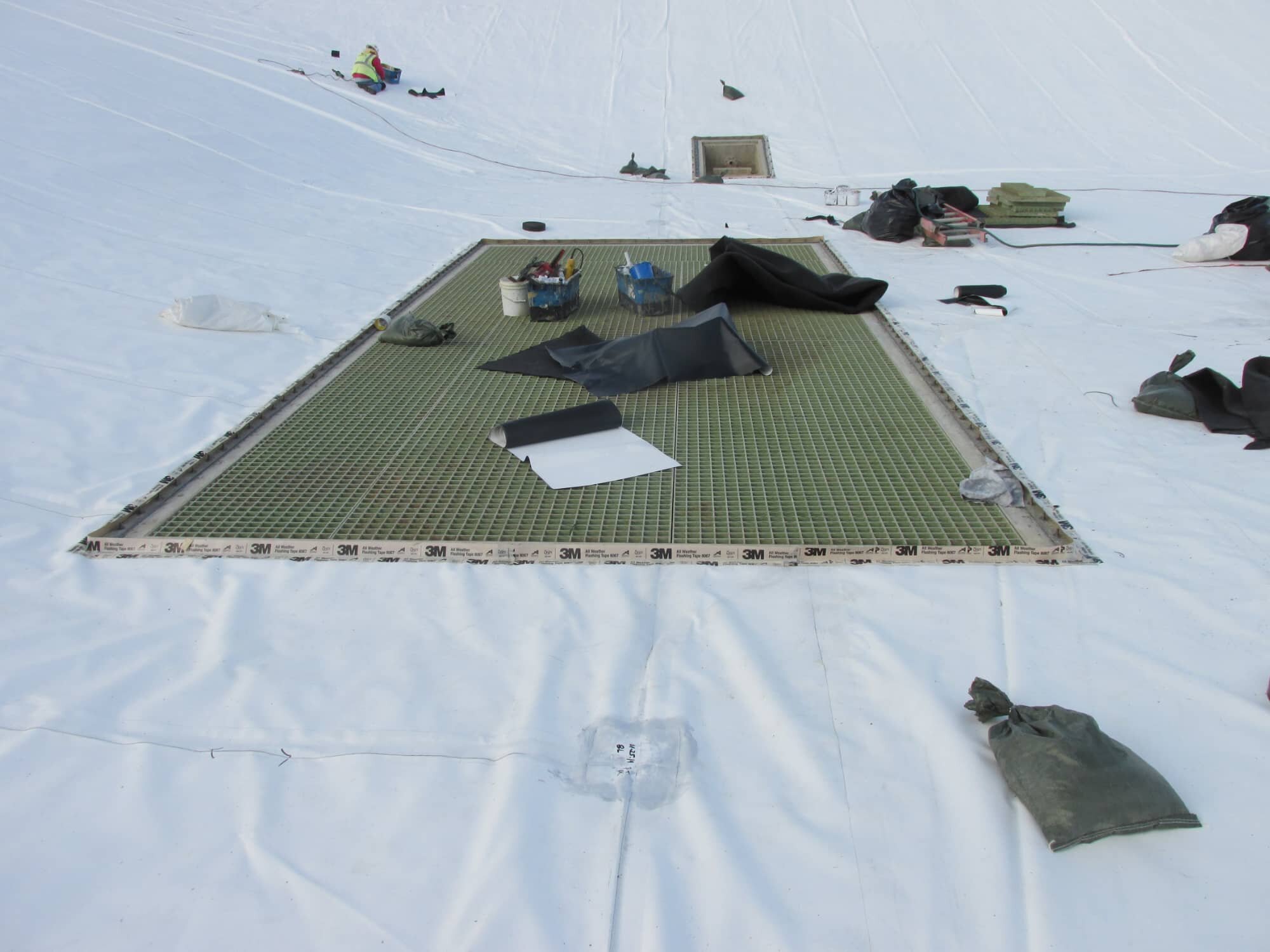

When it comes to installation of a liner system, quality control is the main ingredient for sound reassurance. Clients depend on quality workmanship to prevent costly, post-construction failures that may be detrimental to their work process or business. Our Quality Assurance and Quality Control service minimizes and prevents the chance of incorrect liner installation, liner damages, and/or leaks in the geomembrane. The elements that pertain to the QAQC Service includes:

specifications according to ASTM

and guidelines

equipment

conditions

Consultation for

Containment Systems

Service ID

CNSLT - CMNT

DESCRIPTION

A complete, walk-around site assessment and environmental analysis of your application is performed to determine which survey method would best fit your current situation. A technician would arrive on site and evaluate site conditions along with implementing strategic preparations in order to determine which method would be most effective and cost friendly. Many key elements are factored in during the assessment process such as the following:

After gathering all information and questions have been addressed, on-site recommendations are provided to the Client. A proposal will be generated in the next few days.

Consultation for

PELM® System Installation

Service ID

CNSLT - PELM

DESCRIPTION

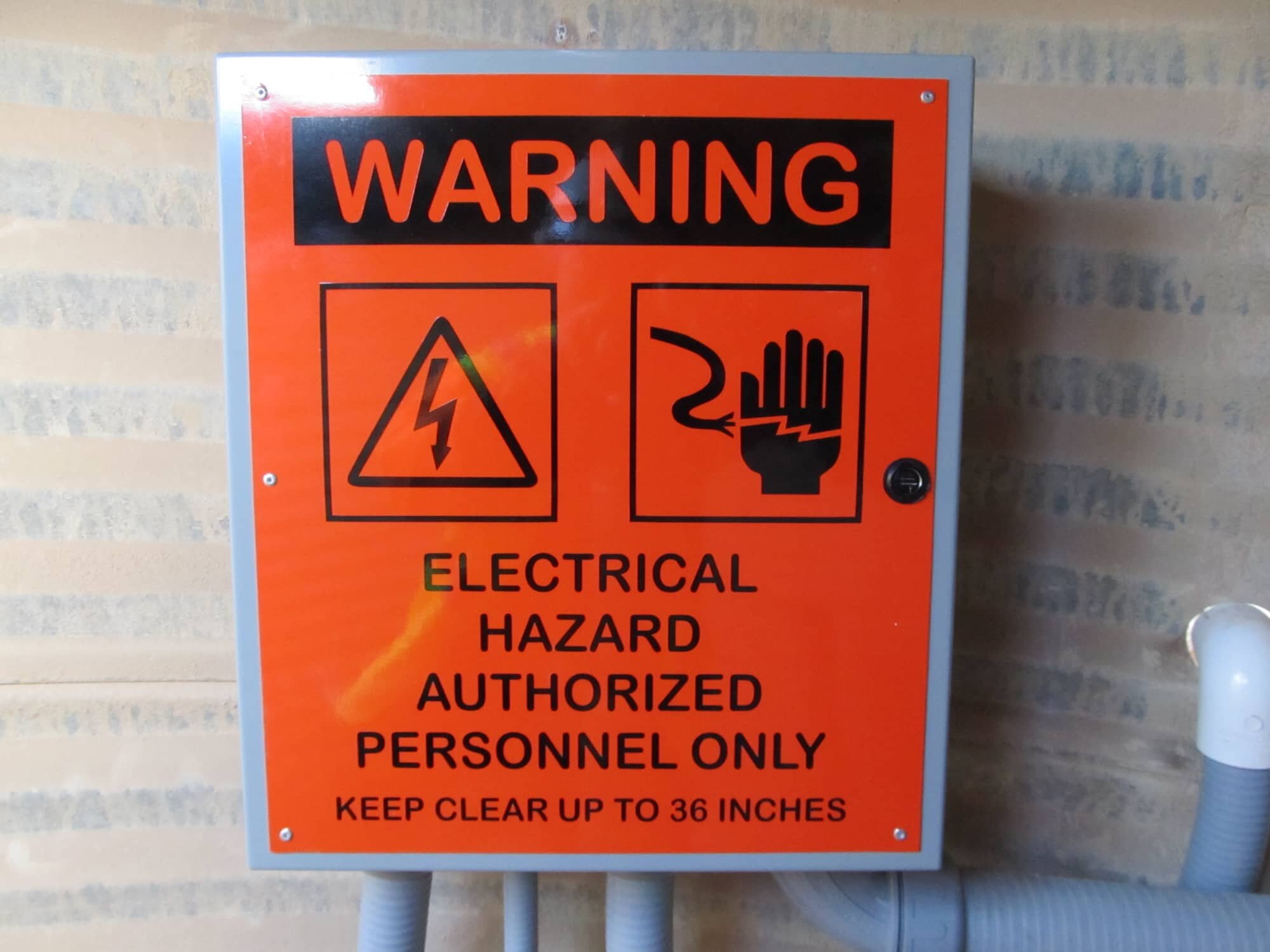

When evaluating a surface impoundment or landfill application for a PELM® System installation, a detailed analysis regarding every key element is provided to the Client. This ranges from the detailed location of current electrodes down to the type of wire required. Distance, orientation, and type of electrodes are critical and play a crucial part in determining the sensitivity of the system. A technician would evaluate the entire application and it's surrounding area to determine electrode locations, ground interferences, or possible system obstructions. The location of the control panels and junction boxes are carefully examined and documented. Major key elements are factored in when installing the system such as:

After the evaluation is complete, a final project specifications sheet is drafted in our facility. A detailed proposal regarding pricing, quantities of parts, manpower, installation period, etc. is generated and provided to the Client.

* PELM® is a registered trademark of Beyond Leak Detection