Maintaining the integrity of the monitoring system or products assures optimal efficiency and prolongs the life span of equipment and electronics. By performing a regular preventative maintenance service, the leak detection system and products remain to operate under safe work conditions and verifies the functionality and sensitivity have been calibrated to maximum level.

Maintenance for

The PELM® System

Service ID

MAINT - PELM

DESCRIPTION

TASKS

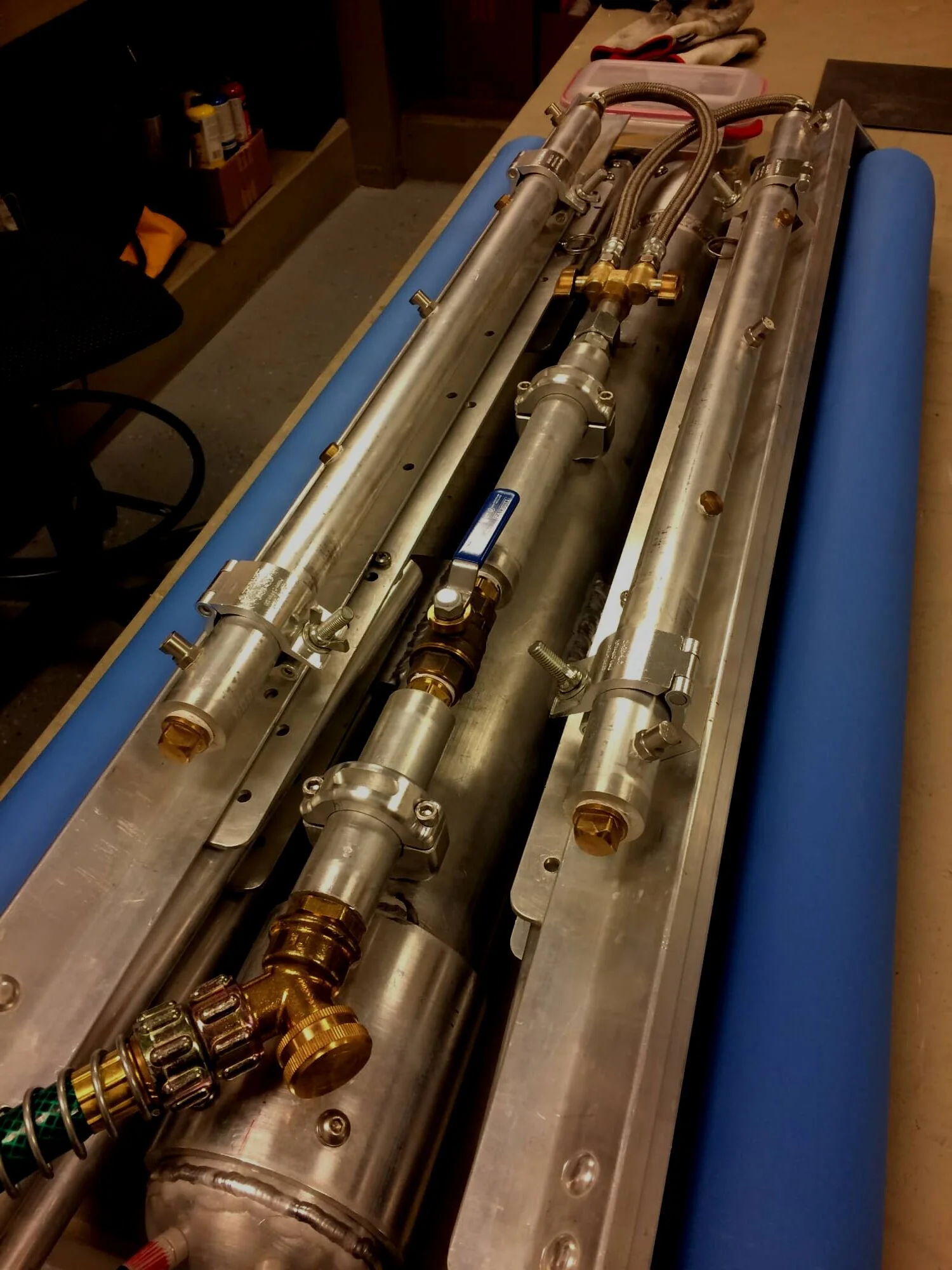

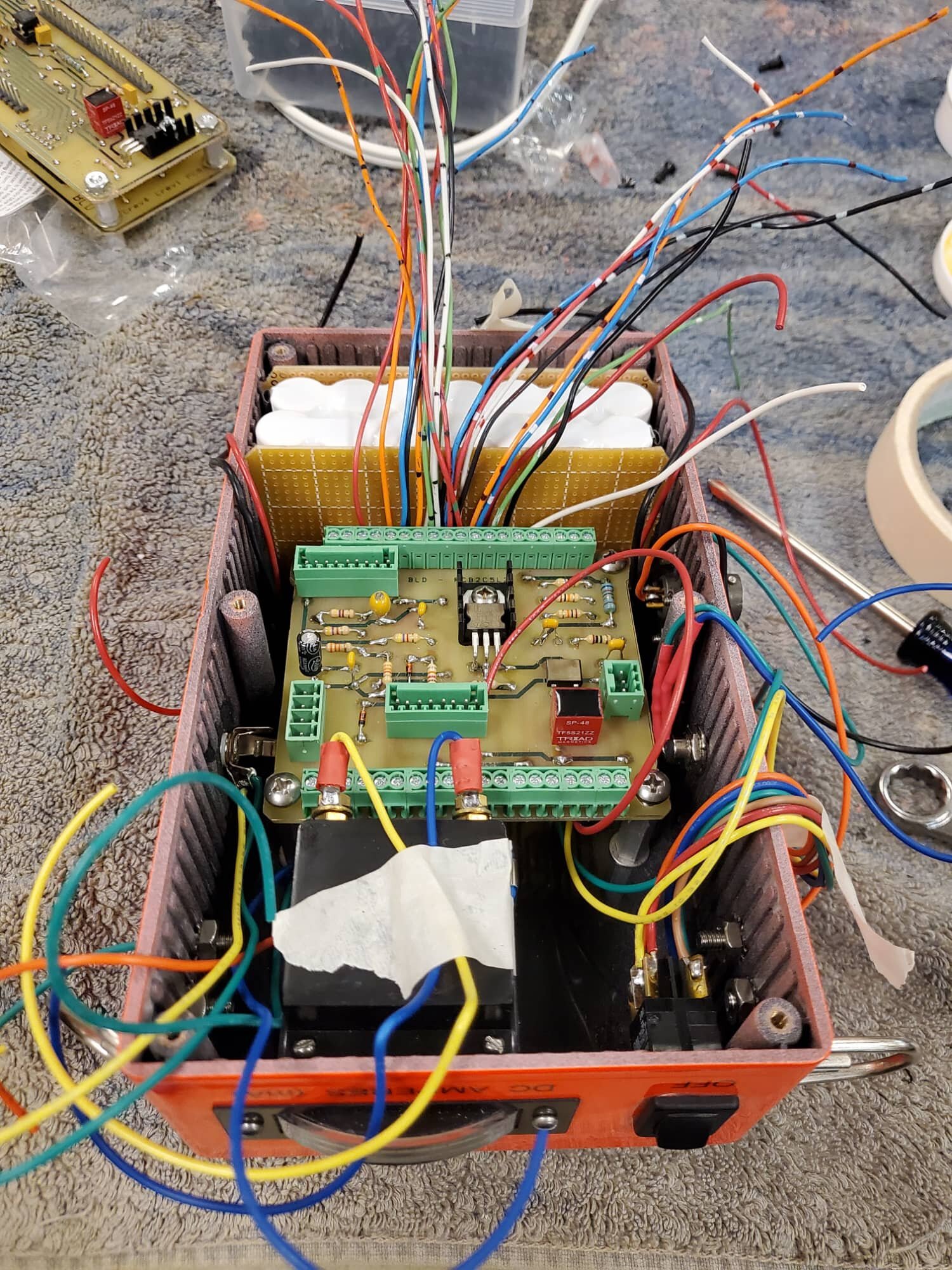

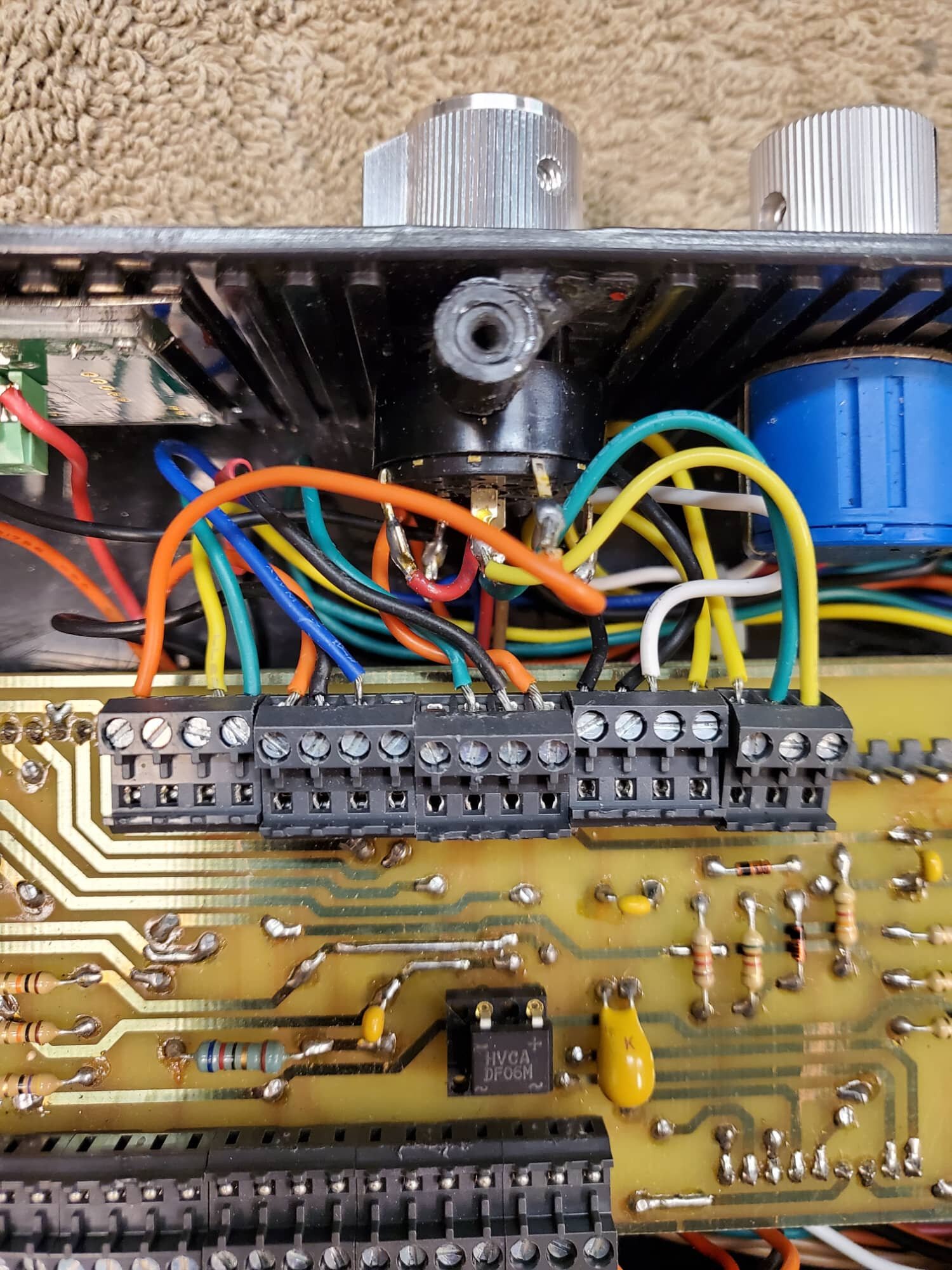

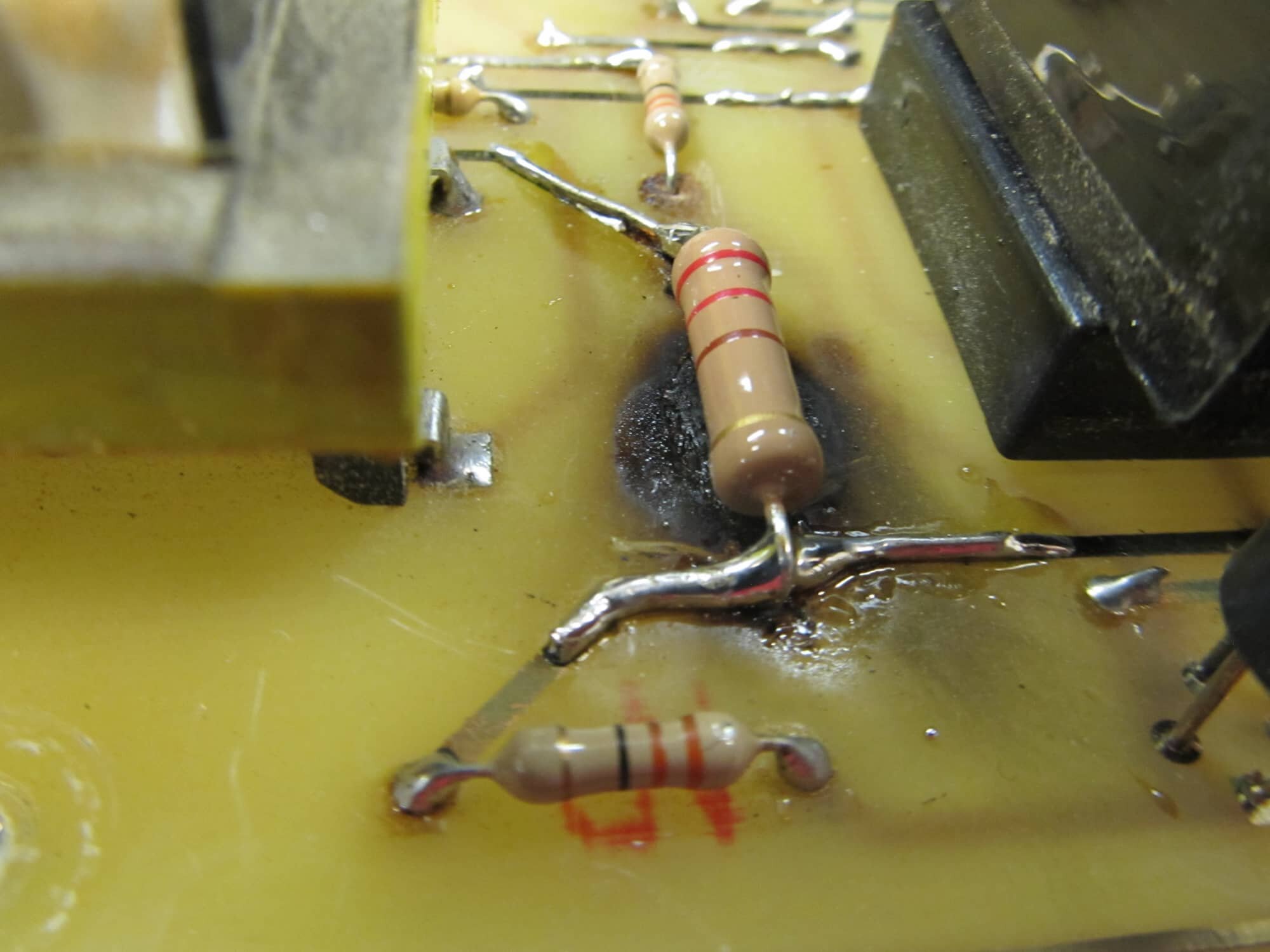

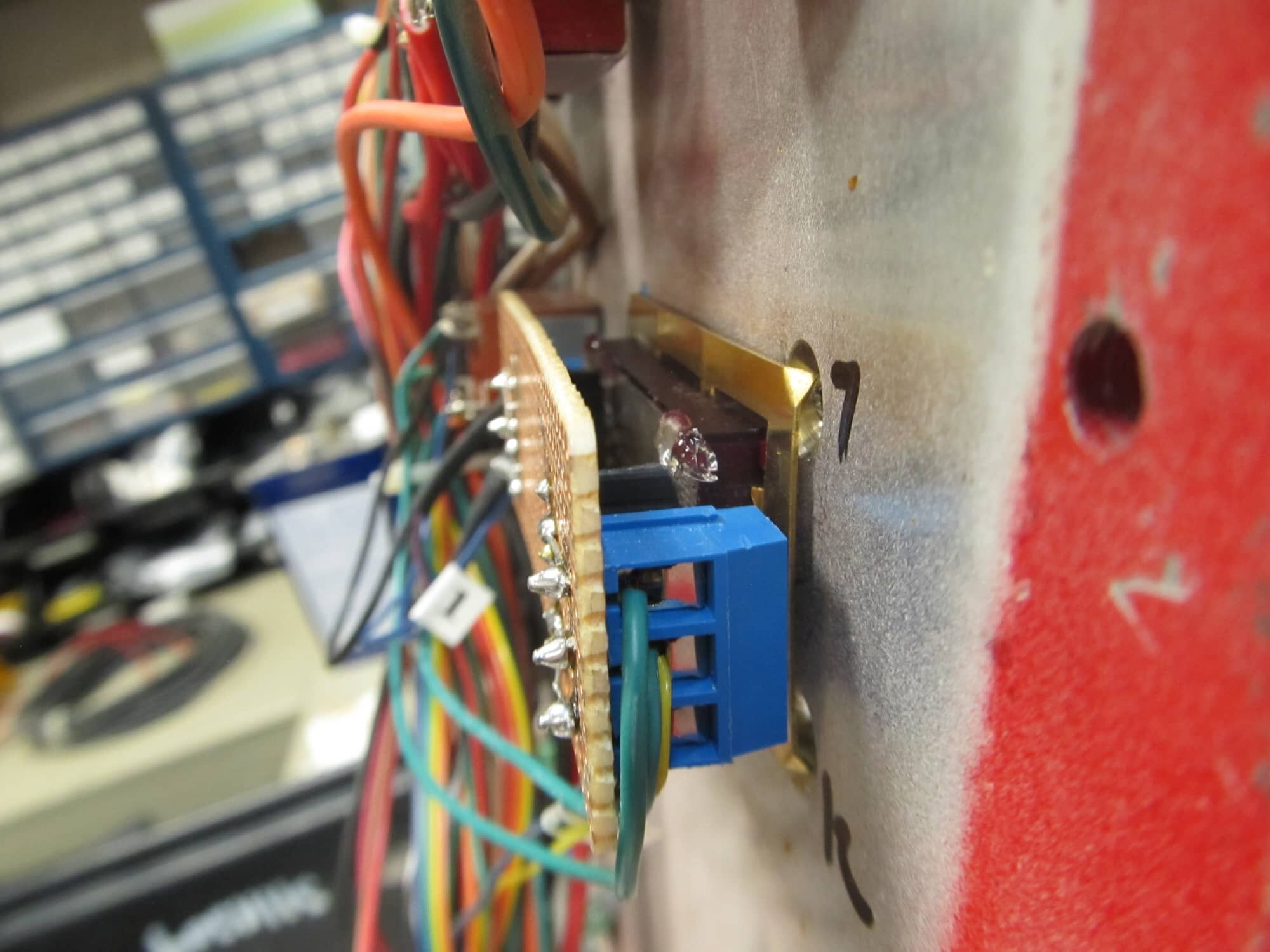

The Preventative Maintenance (PM) Service was developed to serve one purpose: to prolong the functional longevity of the PELM® System. In addition, the program was constructed to locate a leak if one were to occur.

introduced into the leak detection system

measurements at each electrode and determines whether an

electrode has either been disconnected, damaged, or has

malfunctioned

receive data from a sustained resistant value

condition of PELM® System

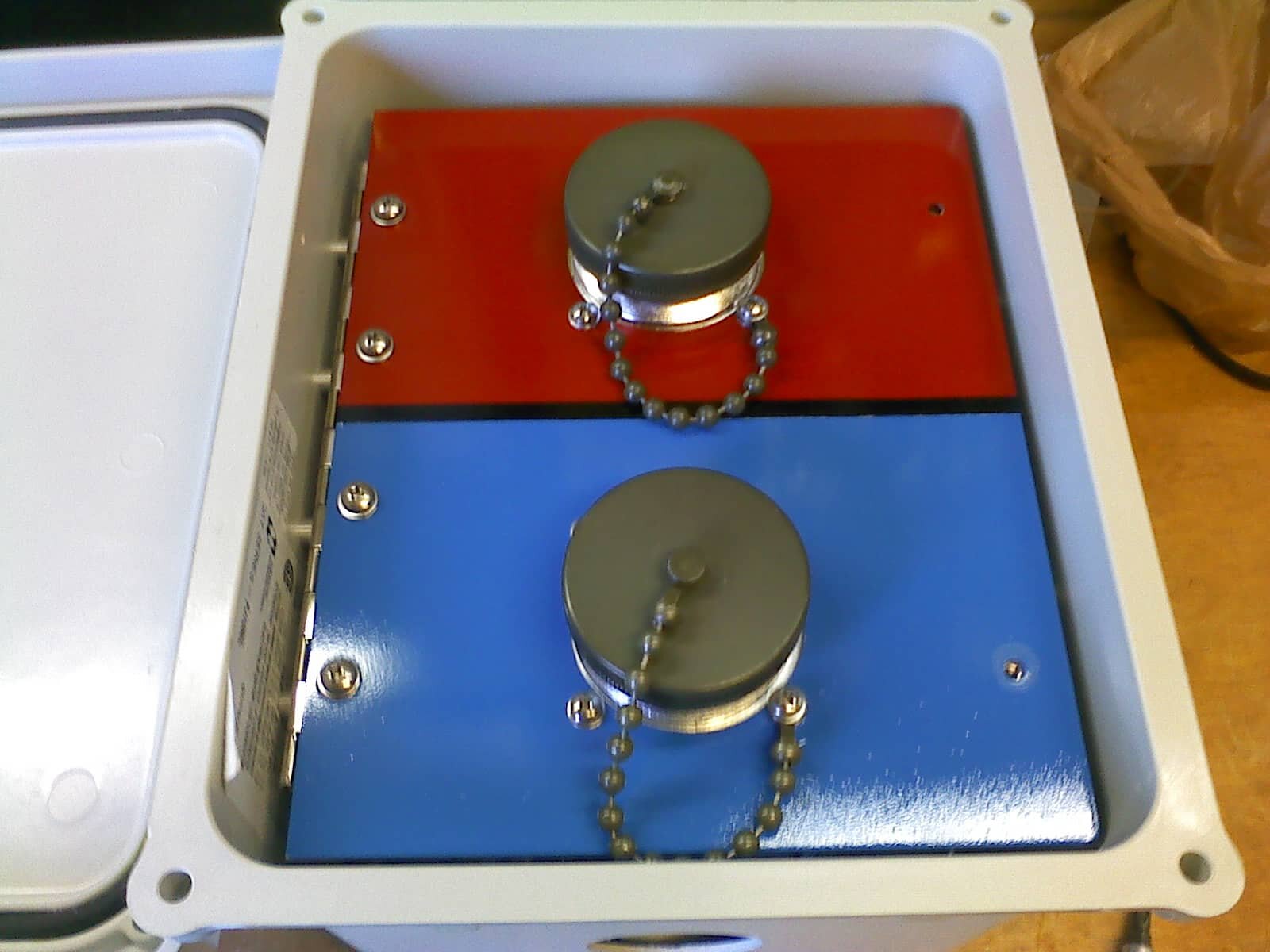

Maintenance for

Leak Detection Products

Service ID

MAINT - PROD

Coming soon. Please check back for service status.

DESCRIPTION

TASKS

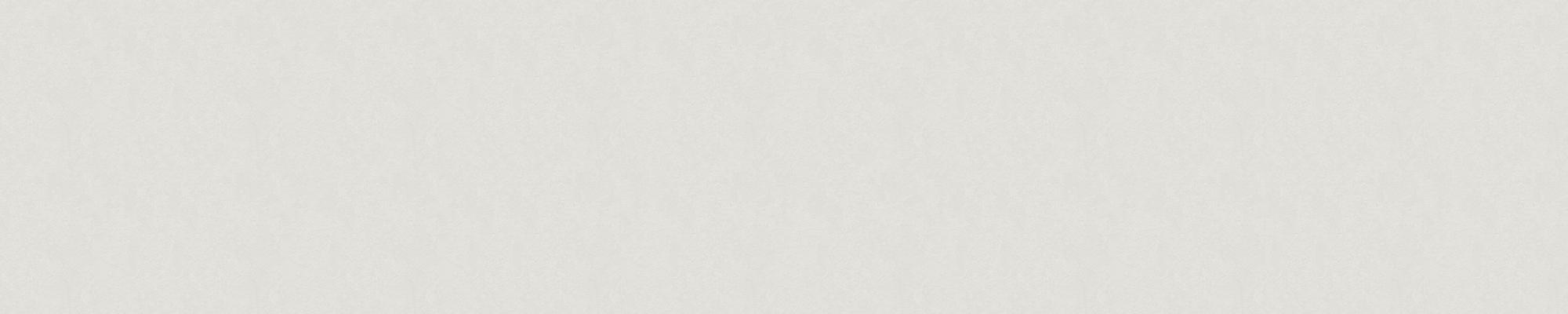

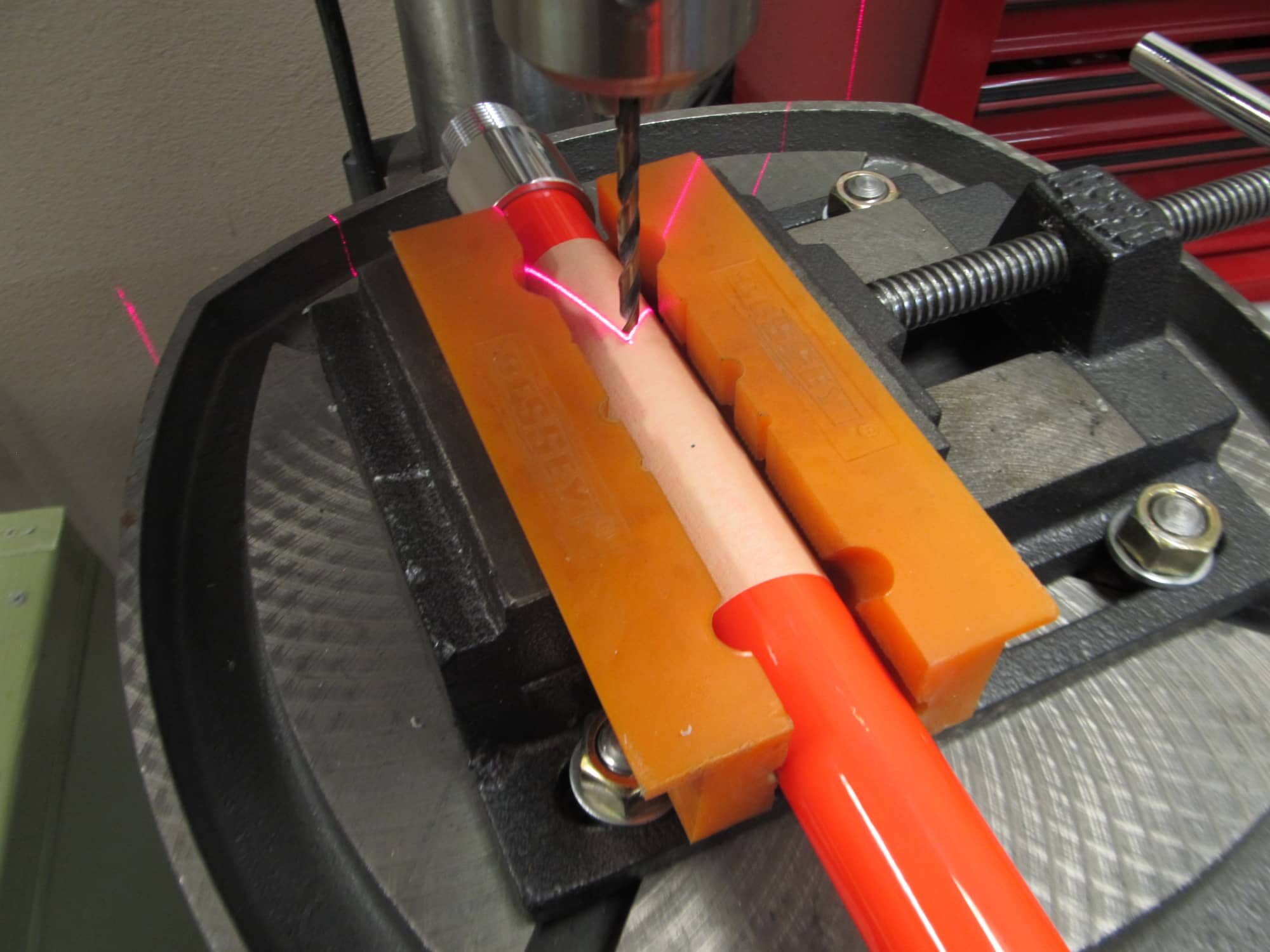

Have a leak detection product that was purchased from us? Want to make sure your probe is functioning to it's full potential? Just like a car vehicle, full inspections are necessary to reduce the probability of a breakdown especially when you least expect it. We've been there and we've done it! That's why we've developed a maintenance program just for our products. Maintenance of our leak detection products not only play a vital role in prolonging the life of the product, but ensures reliability and dependability Clients can trust while working in the field. Depending on the product purchased, the maintenance program tasks for our leak detection products may vary.

connections and checks resistance

maintaining adequate pressure through a measured time

period

expandandable configurations of the product

are leak free

condition of product

* PELM® is a registered trademark of Beyond Leak Detection